Frontier 355

| Download Frontier 355 booklet |  |

Minilab Frontier 355 has a processing capacity of 1,300 prints per hour for a 3R size image and 1,050 prints per hour for a 4R size image.

Frontier 355 Digital Lab System

| Fujifilm Digital Minilab Frontier 355 Main Specifications | ||||

|---|---|---|---|---|

|

|

Input source

|

Print sizes

|

paper widths

|

Frontier 355

|

|

Processing capacity

|

135

|

3R

|

5"

|

Approx. 1300 prints/hr

|

|

4R

|

6"

|

Approx. 1050 prints/hr

|

||

|

10R

|

12"

|

Approx. 200 prints/hr

|

||

|

Advanced Photo System (IX240)

|

3R C/H/P-mixed-format prin

25 exp. roll and index print |

3.5"

|

Approx. 36 rolls/hr

|

|

|

Media prints (digital still cameras with 2 millions pixels)

|

3R

|

5"

|

Approx. 1300 prints/hr

|

|

|

Printable films (using standard or optional film carriers)

|

|

|||

|

Print sizes

|

82.5 x 117 mm ~ 254 x 381 mm.

|

|||

|

Processing chemicals

|

ChemicalsystemCP-48S.

|

|||

| SCANNER & IMAGE PROCESSOR Frontier 355 / Frontier 375 (SP-3000) (Input unit) | LASER PRINTER/PAPER PROCESSOR Frontier 355 (LP1500SC) / Frontier 375 (LP2000SC)) (Output unit) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Frontier 355 Features

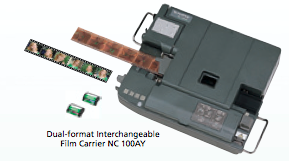

Flexible-use film carrier

Film loading is easier thanks to a Dual-format Interchangeable Film Carrier that accommodates both Advanced Photo System film and 135 film, allowing automatic "one-pass" processing.

Film loading is easier thanks to a Dual-format Interchangeable Film Carrier that accommodates both Advanced Photo System film and 135 film, allowing automatic "one-pass" processing.

Double paper magazines

The two built-in paper magazines can be loaded with paper of different sizes (anywhere from 8.9 to 25.4cm in width) to make it easy to switch back and forth between sizes, and to allow easier auto selection. Automatic loading eliminates paper replacement errors and minimizes paper loss during printing.

The two built-in paper magazines can be loaded with paper of different sizes (anywhere from 8.9 to 25.4cm in width) to make it easy to switch back and forth between sizes, and to allow easier auto selection. Automatic loading eliminates paper replacement errors and minimizes paper loss during printing.

Efficient, time-saving print sorting system

Both the Frontier 355 and 375 models utilize an automatic sorting system to help achieve their remarkably high-capacity output. The 375 includes a 25-order sorter, while the 355 has an 11-order sorter (upgradable to 25-order). Each unit sorts and stacks prints by order for easy filing and delivery. Prints larger than 152mm are fed to a stocker for separate handling.

Both the Frontier 355 and 375 models utilize an automatic sorting system to help achieve their remarkably high-capacity output. The 375 includes a 25-order sorter, while the 355 has an 11-order sorter (upgradable to 25-order). Each unit sorts and stacks prints by order for easy filing and delivery. Prints larger than 152mm are fed to a stocker for separate handling.

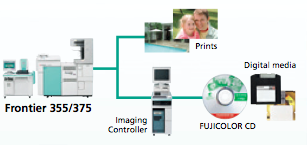

Single-scan digitization

Film needs to be scanned only once, since image data from the film is digitized at the same time as regular prints are produced. Operations like the creation of a FUJICOLOR CD or the storage of image data for later use don`t necessitate an extra scanning step.

Film needs to be scanned only once, since image data from the film is digitized at the same time as regular prints are produced. Operations like the creation of a FUJICOLOR CD or the storage of image data for later use don`t necessitate an extra scanning step.

One-touch chemical replenishment

Because the Frontier`s chemical system is all contained in a single cartridge, operators enjoy the benefits of one-touch loading and automatic mixing. This simplifies the task and virtually eliminates the possibility of mixing errors.

Because the Frontier`s chemical system is all contained in a single cartridge, operators enjoy the benefits of one-touch loading and automatic mixing. This simplifies the task and virtually eliminates the possibility of mixing errors.

Auto calibration

The Automatic Calibrator (AD200), located on top of the Frontier, simplifies daily maintenance by automatically adjusting color and tone reproduction to a specified standard, for print quality that`s consistent from one day to the next.

Perfect one-channel print system

This system automatically detects the size and type of film, controlling all processing while eliminating the need for time-consuming manual adjustment of scanning-unit settings by the operator. Different film types (negatives, monochrome film, reversal film, and even digital camera prints) are all handled together, so there`s no need to separate different kinds of film.

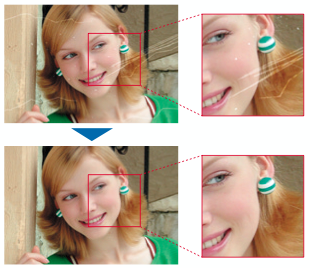

Image Intelligence

Imperfections caused by scratches and dust on the original negative are especially noticeable in extra-large-size reprints, but the Frontier 355/375 cleans up these flaws using an exclusive correction technology. First, the film is exposed to infrared light during the scanning step - infrared rays pass straight through the color dyes on the film (which form the image), but are deflected by scratches and dust particles. Once blemishes are detected in this way, the resulting streaks or spots are corrected using extrapolated image data from surrounding areas of the film. The result is a natural-looking final image. Scratch and dust elimination can be applied automatically to all frames during the initial print processing run.

Imperfections caused by scratches and dust on the original negative are especially noticeable in extra-large-size reprints, but the Frontier 355/375 cleans up these flaws using an exclusive correction technology. First, the film is exposed to infrared light during the scanning step - infrared rays pass straight through the color dyes on the film (which form the image), but are deflected by scratches and dust particles. Once blemishes are detected in this way, the resulting streaks or spots are corrected using extrapolated image data from surrounding areas of the film. The result is a natural-looking final image. Scratch and dust elimination can be applied automatically to all frames during the initial print processing run.

The distracting appearance of red pupils due to a bright flash can be corrected easily with this function. Operator-selected frames displayed on the monitor can automatically have red-eye appearance detected and corrected. Operations can be performed on the first pass, reducing the need for man

The distracting appearance of red pupils due to a bright flash can be corrected easily with this function. Operator-selected frames displayed on the monitor can automatically have red-eye appearance detected and corrected. Operations can be performed on the first pass, reducing the need for man

- Backlight correction

Independent image density adjustment is performed on overly bright background areas and overly dark foreground figures, automatically adjusting their relative brightness within the photo. - Sharpness adjustment

Fujifilm`s proprietary HyperSharpness process enhances the edge definition of objects, colors and shadows while compensating for film grain, to produce photos that are crisper and clearer. - High-contrast correction

In flash shots against a dark background and in shots using too bright a flash, the foreground figures can appear too light and washed out while the background is dark and murky. High- contrast correction adjusts the relative brightness of foreground figures and background. - Over- / under-exposure compensation

When an underexposed or an overexposed negative is detected, the density and contrast of the image can be adjusted automatically to bring the image closer to its proper exposure level.